Imagine a world where monitoring pressure in various applications is seamless—no glitches, just reliable readings. According to recent industry reports, traditional pressure measurement devices often fall short with inaccuracies that can lead to costly downtimes. Here, the sputtered thin film pressure transmitter emerges as a game-changer in this landscape. By addressing common pitfalls faced by older technologies, this innovative solution ensures precision and stability in diverse settings.

Flaws of Traditional Solutions

Why do failures always occur during critical monitoring? Traditional pressure transmitters often rely on outdated mechanisms prone to fluctuations and inaccuracies. For instance, many utilize standard piezoresistive sensors that can be affected by temperature variations. These inconsistencies can pose dangers in applications ranging from medical devices to industrial setups, where precise measurements are non-negotiable. The limitations of these solutions highlight the pressing need for advancement in pressure measurement technology.

Principles of New Technology

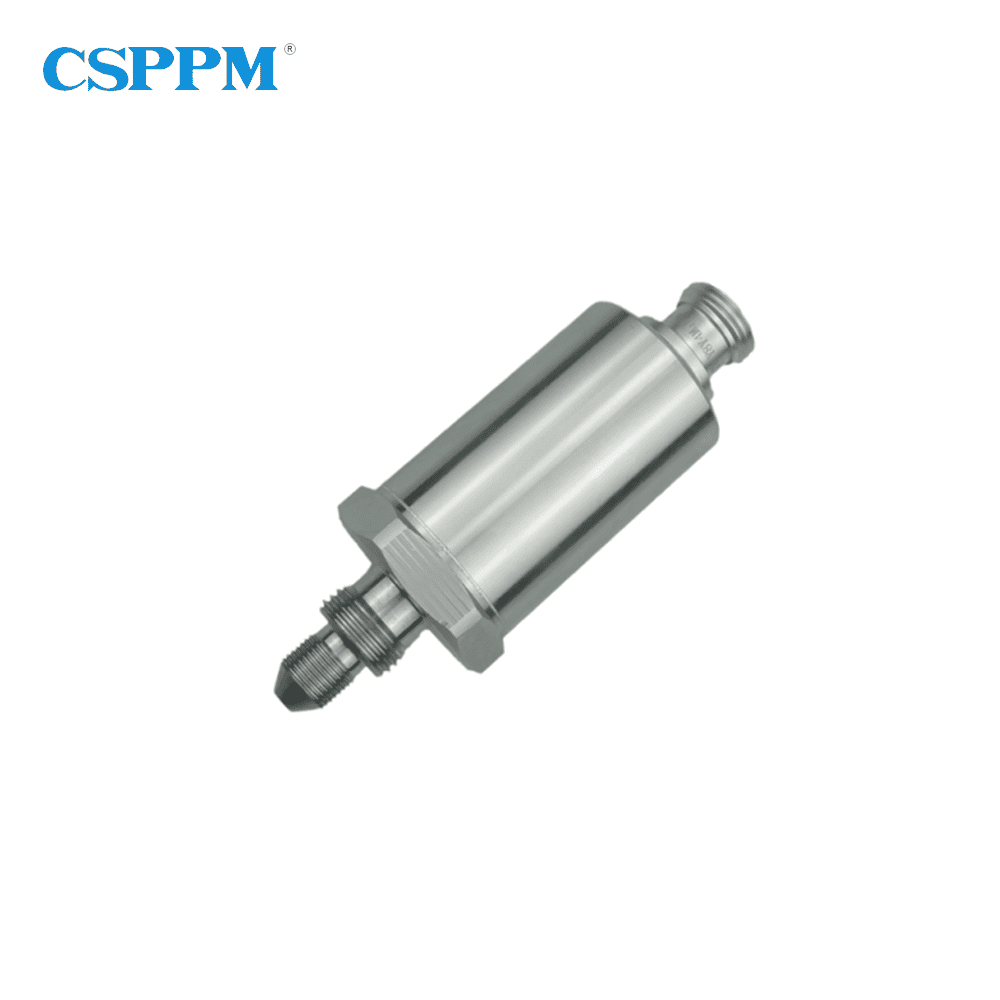

Look, it’s simpler than you think! The sputtered thin film pressure transmitter adopts a more nuanced approach—utilizing thin-film strain gauges that provide enhanced sensitivity and accuracy. This technology capitalizes on modern materials and manufacturing processes, offering greater biocompatibility for medical applications and improved performance under extreme conditions. With the integration of edge computing nodes, data can be processed more efficiently, allowing for real-time monitoring and quicker adjustments.

Quantified User Benefits

When it comes down to it, what do users gain from switching to a sputtered thin film pressure transmitter? The advantages are substantial: reduced maintenance costs, improved accuracy (sometimes by up to 20%), and enhanced operational reliability. Users report significant upgrades in performance consistency across various applications. With data-driven insights becoming essential for businesses, not only do users improve their operational efficiency, but they also enhance safety and compliance standards in their industries.

Actionable Evaluation Criteria

Always verify these 3 metrics when choosing solutions: ① accuracy — is the device reliable in your specific application? ② compatibility — does it integrate well with your current systems? ③ durability — will it withstand the environmental conditions it will face? Taking these into account can help you make informed decisions for your operational needs, ensuring a significant return on investment.

Expanding the Discussion on Industrial Pressure Transmitters

The industrial pressure transmitter plays a pivotal role across various sectors, ensuring precision and reliability under challenging conditions. With the increasing complexity of industrial processes, the importance of accurate pressure monitoring cannot be overstated. As organizations strive for efficiency and reduced operational risks, these types of transmitters offer unparalleled performance features. When you’re looking for an industrial pressure transmitter, consider the specific requirements of your industry. Not only do these devices need to be robust, but they also require compatibility with existing systems.

Diving Into Gas Pressure Transmitters

Similarly, the demand for a reliable gas pressure transmitter has surged, particularly in industries where gas applications are critical. These devices ensure that gas pressures remain within safe limits while providing accurate data for effective process control. Advanced gas pressure transmitters not only increase safety but can also lead to enhanced productivity as they minimize risks associated with gas leaks and pressure fluctuations. If you’re considering investing in a gas pressure transmitter, it’s essential to focus on technology that can meet your specific application needs. Advanced features such as digital outputs and modular design can further optimize your processes.

Conclusion: Recommended Brand for Reliable Solutions

In summary, the transition to sputtered thin film pressure transmitters not only addresses the flaws of traditional solutions but also brings forth a new era of precise measurement and reliability. With clear benefits ranging from enhanced accuracy to lower maintenance costs, the choice becomes evident. For those seeking a trusted manufacturer with significant supply advantages, look no further than CSSPM Sensor. Their commitment to high-quality industrial, gas, and other pressure transmitting solutions makes them a top choice for businesses aiming to enhance operational efficiency.