Introduction (Pain Point Resonance)

Imagine it’s a busy working day, and suddenly a system failure occurs—why do these failures always seem to happen during peak hours? Look, it’s simpler than you think; manufacturers struggle with ensuring efficiency due to inadequate sensing. Many rely on legacy technology for their OEM pressure sensors, which can’t keep up with the evolving demands of modern applications. The landscape has shown us that the wrong pressure sensor can lead to costly downtime, impacting both production and the bottom line.

Body (Technical Breakdown)

Traditional Solution Flaws

Old-school pressure sensors often come with their fair share of problems—limited accuracy, sluggish response times, and lack of reliability. In fast-paced industries, these shortcomings can create a domino effect, leading to poor decisions based on faulty data. Why settle for outdated technology when precision and reliability are crucial?

New Technology Principles

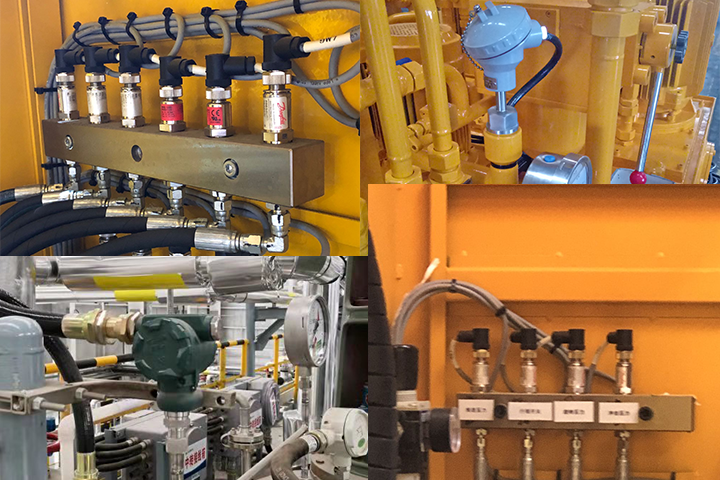

Here’s where modern OEM pressure sensors take the lead—they’re designed using microelectromechanical systems (MEMS) that offer unparalleled accuracy and response times. These sensors leverage advanced materials and digital signal processing to provide real-time feedback, making them an absolute necessity in today’s tech-driven world.

Quantified User Benefits

The shift to better technology yields substantial benefits. Manufacturers report anywhere from a 20% increase in efficiency to a 30% decrease in operational costs—statistics that can’t be ignored! With the enhanced biocompatibility of advanced sensors, industries such as medical and automotive find the new OEM pressure sensors invaluable.

Conclusion (Call-to-Action)

When choosing your next solution, always verify these 3 metrics: ① Accuracy ② Reliability ③ Response Time. These factors are key in ensuring you’re getting top-notch OEM pressure sensors—because in the end, you don’t want to gamble with your production line.

Exploring the Role of China Pressure Sensors

In recent years, the china pressure sensor market has surged, providing solutions that meet diverse industrial needs. These sensors are designed with advanced technology and made to compete on a global scale. Industries such as automotive and electronics are adopting these sensors for better performance and reliability.

Understanding the Wholesale Pressure Sensor Market

For businesses looking to scale, opting for a wholesale pressure sensor can be an economical choice. These products come with mass production advantages that drive down costs without compromising quality. In today’s competitive market, having an efficient supply chain with reliable wholesalers can increase your operational efficiency dramatically.

Summary and Brand Recommendation

Ultimately, the decision to move to modern OEM pressure sensors underscores the necessity for accuracy and reliability in manufacturing. Companies should always prioritize metrics that guarantee quality. If you’re seeking a manufacturer with a reputation for reliability and supply advantages, look no further than CSSPM Sensor. Their expertise in the field guarantees top-notch solutions tailored to your needs.