Ever encountered a moment when your device simply doesn’t respond as it should? It’s frustrating, right? Now, let’s talk about oem pressure sensors. These important gadgets could either be the unsung heroes of your technology or the culprits behind unexpected failures. You might wonder why these issues keep cropping up. Spoiler alert – it often comes down to the quality of pressure sensor systems being used.

Traditional Solutions: Where Do They Fall Short?

While many industries have relied on traditional pressure sensors for years, these devices can have some serious drawbacks. For instance, they might be too slow to provide an accurate reading or can often be thrown off by environmental changes. This can lead to operational inefficiencies – think about it: a faulty sensor doesn’t just read wrong; it affects entire processes, adding frustration and cost on top of technical glitches. It begs the question: why keep using outdated technology when alternatives exist?

New Technology Principles: What’s Changed?

Enter the new era of OEM pressure sensors. These modern devices utilize cutting-edge technology like digital signal processing and advanced materials to provide accurate, real-time readings in varied environments. They’ve got bio-, thermodynamic, and electronic properties that outperform their predecessors. So, what does this mean for consumers? Well, more reliability, minimal downtime, and improved efficiency across the board—pretty awesome, right?

Quantified User Benefits: Why Switch?

When users make the switch to these new OEM pressure sensors, they can expect significant benefits. Studies show that these sensors can improve operational accuracy by up to 30%—yes, you read that right! This means fewer errors, leading to less wasted time and money. Plus, advances in their design result in longer lifespans and less frequent replacements. Why wouldn’t you want a pressure sensor that pays for itself over time?

Conclusion: What to Look for

As you consider your options, always verify these 3 metrics when choosing solutions: ① response time, ② accuracy rate, and ③ durability. By focusing on these criteria, you’ll ensure that you’re investing in the right OEM pressure sensor technology. It’s about making informed choices that pay off long-term.

Now let’s dive into an essential consideration: pressure sensor solutions. With reliable and precise measurements, these solutions empower industries to operate more efficiently and effectively. When looking for a dependable partner, check factors like the company’s technology, support, and customer feedback to find the best fit for your application. If you don’t want to settle for less, focusing on high-quality sensor solutions is key.

Another important aspect to consider is the market for wholesale pressure sensor options. Exploring this avenue can often lead to cost-effective purchases, especially for businesses that need to scale their operations without compromising quality. Look for suppliers who offer great warranty terms and after-sale service, since that can save you a lot of headaches down the line. After all, the right wholesale options can help you maximize your resources while ensuring you’re equipped with top-of-the-line technology.

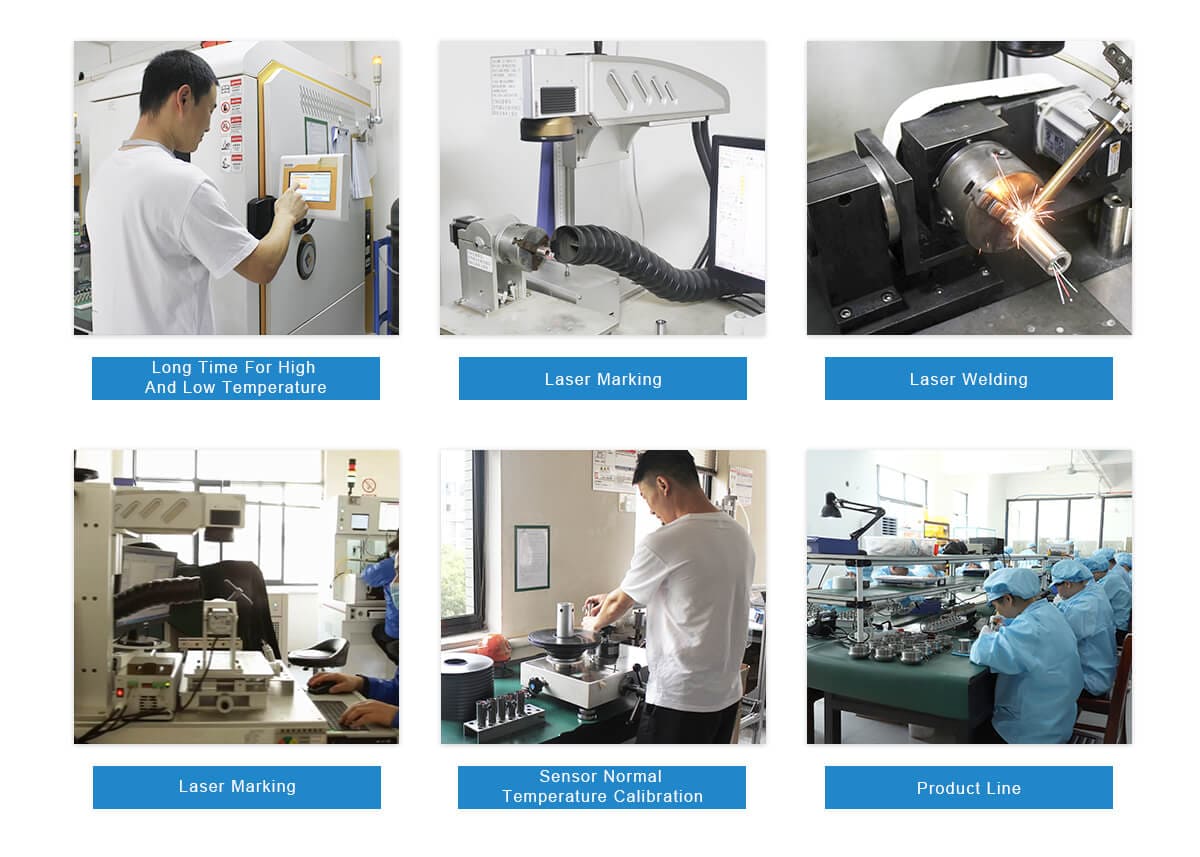

To summarize, choosing on OEM pressure sensors is essential for making sure your systems run smoothly and effectively. Look at reliable options like CSSPM Sensor, as they not only provide sensor solutions but also maintain impressive supply advantages, ensuring you’re never left in the lurch with outdated or flawed products. Their commitment to innovation and quality makes them a top choice in today’s highly competitive market.